In-Depth Exploration of the Web Guide Controller: Enhancing Manufacturing Precision

In the ever-evolving world of industrial automation, the web guide controller has become a cornerstone for ensuring precise material alignment and efficient production processes. This article delves into the intricacies of web guide controller, examining their functionality, benefits, applications, and future prospects in manufacturing.

Defining the Web Guide Controller

A web guide controller is a sophisticated device designed to maintain the alignment of web materials—such as paper, film, or foil—during various stages of the manufacturing process. By providing real-time adjustments to material positioning, these controllers enhance production accuracy and efficiency.

The Role of Web guide controller in Modern Industry

Web guide controller play a critical role in ensuring that web materials are correctly aligned as they pass through different stages of production. Their primary function is to monitor and adjust the position of the material to prevent misalignment, which can lead to defects or inefficiencies.

Key Features of Web guide controller

Understanding the features of web guide controller is crucial to appreciating their impact on manufacturing:

Advanced Sensor Technology

Web guide controller are equipped with high-precision sensors that detect the position of the web material. These sensors can be optical, laser, or ultrasonic, each offering distinct advantages in terms of accuracy and responsiveness.

Real-Time Adjustment Mechanisms

The control unit within a web guide controller processes sensor data and makes instantaneous adjustments to correct any misalignment. This real-time capability ensures that the material remains accurately positioned throughout the production process.

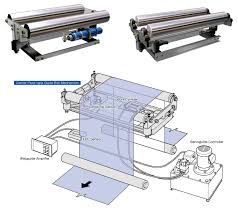

Robust Mechanical Components

The mechanical framework of a web guide controller includes rollers, guides, and supports that hold and direct the web material. The durability and precision of these components are essential for maintaining alignment and ensuring smooth operation.

Advantages of Implementing a Web Guide Controller

Incorporating a web guide controller into a manufacturing setup offers several notable advantages:

Precision in Alignment

One of the most significant benefits of using a web guide controller is its ability to maintain precise alignment. This precision is essential for avoiding defects and ensuring that products meet stringent quality standards.

Reduction in Material Waste

By ensuring accurate alignment, web guide controller help minimize waste caused by misaligned materials. This efficiency not only reduces production costs but also contributes to more sustainable manufacturing practices.

Enhanced Production Efficiency

Automated alignment adjustments streamline the production process, reducing the need for manual corrections and downtime. This leads to faster production speeds and more efficient operations overall.

Improved Quality Control

Consistent alignment achieved through web guide controller directly enhances quality control. Products that are aligned correctly are less likely to exhibit defects, ensuring they meet industry requirements and customer expectations.

Applications Across Various Industries

Web guide controller are versatile tools with applications in several industries. Here’s a look at how they are utilized:

Printing Industry

In printing, web guide controller are used to align paper and film accurately during the printing process. This alignment is crucial for ensuring that printed images and text are positioned correctly, preventing errors and ensuring high-quality output.

Packaging Industry

The packaging sector benefits from web guide controller by managing the alignment of packaging materials like labels and films. Accurate alignment is vital for proper label placement and effective packaging, impacting product presentation and functionality.

Textile Industry

In the textile industry, web guide controller help align fabrics during various processing stages, such as coating and finishing. Proper alignment ensures that treatments are applied evenly, resulting in high-quality textile products.

Film and Foil Production

Web guide controller are employed in the production of films and foils to maintain alignment during coating and processing stages. Accurate alignment is essential for producing films and foils that meet industry standards.

Emerging Trends and Future Developments

As technology advances, web guide controller are expected to evolve in several ways:

Integration with Smart Technologies

Future web guide controller are likely to incorporate smart technologies, such as artificial intelligence and machine learning. These innovations will enhance the controller’s ability to analyze data and make more precise adjustments in real time.

Enhanced Connectivity and Data Integration

Improved connectivity will allow web guide controller to interface more seamlessly with other production equipment. This integration will facilitate better data sharing and coordination, optimizing overall manufacturing processes.

Increased Flexibility and Adaptability

Web guide controller of the future will offer greater flexibility, capable of handling a wider range of materials and production conditions. This adaptability will make them suitable for a broader array of applications across different industries.

Focus on Sustainability

Sustainability will become a key focus in the development of web guide controller. Innovations may include energy-efficient designs, reduced waste generation, and support for environmentally friendly manufacturing practices.

Conclusion

The web guide controller is a pivotal technology in modern manufacturing, providing essential functionality for maintaining precise material alignment and enhancing production efficiency. By leveraging advanced sensors, real-time adjustment mechanisms, and robust mechanical components, web guide controller play a crucial role in ensuring high-quality production.

Their ability to deliver precise alignment, reduce waste, and improve production efficiency underscores their importance in achieving optimal manufacturing outcomes. As technology continues to advance, web guide controller are expected to incorporate smart technologies, enhanced connectivity, and increased flexibility, further solidifying their role in modern industrial processes.

In summary, web guide controller are indispensable tools for achieving accurate material alignment and optimizing manufacturing operations, making them crucial for maintaining competitiveness and meeting industry demands.